The ultimate simple mechanism Single-stage, Three-station Machines

By dramatically improving the characteristics of plastics,

biaxial stretch-blow container molding technology has become an indispensable part of our modern lives.

Direct Heatcon is a unique molding technology developed by Aoki that eliminates the need for reheating by enabling preforms to be injection molded and heat conditioned at the same time.

With Direct Heatcon technology, raw material is molded into finished containers in just three stations.

The manufacture of high quality, high strength, thin-walled, lightweight containers depends on precision heat conditioning. Direct Heatcon opens the way to higher added value container molding by enabling this heat conditioning to be carried out simultaneously with injection molding.

Molding containers directly from raw material on a single machine using the minimum number of molding steps minimizes the risk of breakdowns and defects.

By using residual heat from the process of injection molding preforms from raw material, Direct Heatcon eliminates preform re-heating costs, reduces preform cooling time, and enables chillers to be downsized. This can drastically reduce unit molding costs and enable higher volume production.

Transportation costs can also be reduced, since Direct Heatcon eliminates the need for preform transportation that frequently constitutes a part of the reheating method.

Technology that realizes your ideas and concepts

With molding systems that involve reheating preforms, there is always a layer of air between the heater and preform that results in a tendency for temperatures throughout the preform to equalize, and makes creating an accurate temperature differential that much more difficult.

Because Aoki's Direct Heatcon molding technology enables preform heat conditioning to be carried out simultaneously with injection molding, meticulous and precise temperature control of the preform is possible.

By controlling preform wall thickness, injection pressure, injection speed and cooling time, as well as creating an accurate temperature profile, the single stage, three-station mechanism enables preforms to be stretch-blown promptly while still in their optimum temperature profile.

With an Aoki machine, you can mold containers that remain true to your ideas.

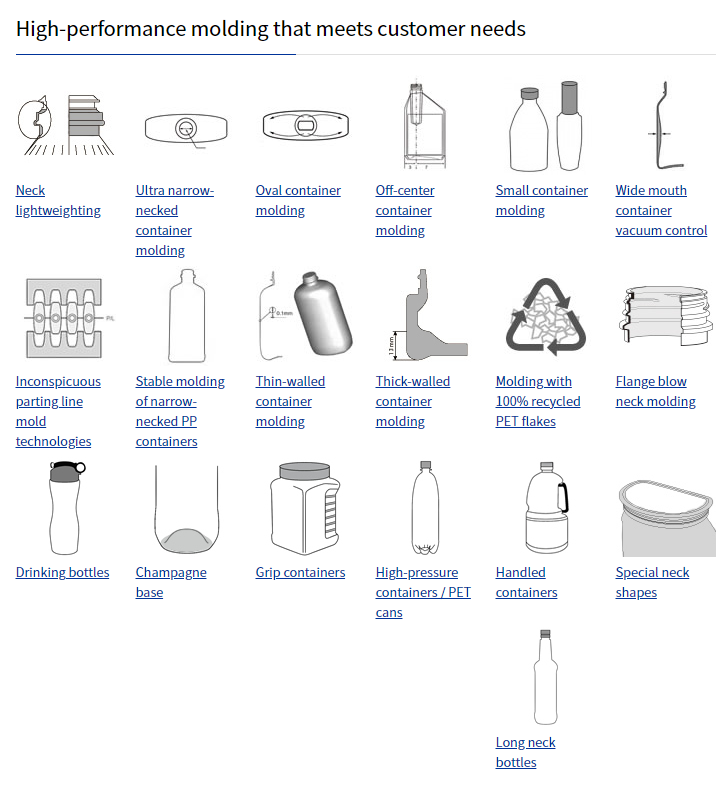

Aoki's container molding technologies

We have been in business for over 40 years, and during that time we have continued to pursue

the potential for plastic containers using our unique injection stretch-blow molding technology.

Over 20,000 different container types have been produced using our container development technology, which continues to evolve to this day. We can leverage our extensive experience and understanding of the characteristics of plastics to propose new possibilities.

Aoki's Production Concept

Creating Packaging Culture

Plastic containers come with a range of excellent characteristics and we are pursuing even greater possibilities for them. By continually improving molding technologies that utilize the functionality of plastic materials, we hope to make the lives of people throughout the world even more convenient and comfortable than they are now. We create packaging culture though container development by researching easier-to-use and more convenient container shapes, developing high-performance containers that utilize the characteristics of the molding materials, and providing new ideas for

using plastic containers.